How to Cut Aluminum Flashing

April 15, 2025 | By Beth | Filed under: Blog

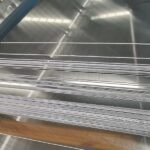

Let’s talk about the best methods for cutting aluminum flashing efficiently. When it comes to working with this material, precision is key. Many homeowners attempt this task themselves, but consulting with devoted metal roof installers can provide valuable insights into proper techniques and safety measures. The process involves several critical steps that significantly impact your project’s outcome. Understanding the right tools, measurement techniques, and cutting approaches will help you achieve professional results whether you’re working on a small repair or a larger roofing project.

Choosing the Right Tools

When cutting aluminum flashing, tin snips are the preferred tool for precise and clean cuts. These snips come in three main varieties: straight-cut, left-cut, and right-cut, each designed for specific cutting needs. Straight-cut snips work best for long, straight cuts, while left-cut and right-cut snips excel at making curves in their respective directions. Selecting the appropriate snips based on your cutting requirements ensures accurate results. Always wear safety gloves and goggles to protect yourself from sharp edges and metal fragments. Keep your tin snips’ blades sharp for efficient cutting. Proper tool selection and maintenance are crucial factors in achieving clean cuts when working with aluminum flashing.

Measuring and Marking

To ensure accurate cuts, carefully measure and mark the aluminum flashing before cutting with tin snips. Here are three essential steps for precise measurements and markings:

- Use a quality tape measure: Begin by measuring the exact length of aluminum flashing needed for your project. Use a sturdy, reliable tape measure that provides accurate readings.

- Mark with a sharp pencil: After determining measurements, use a sharp pencil to mark the cutting lines on the aluminum flashing. Create distinct, visible marks to guide your cutting.

- Double-check measurements: Verify all measurements before cutting to avoid errors. Accurate measurements and clear markings are crucial for achieving clean, precise cuts with tin snips.

Using Snips for Straight Cuts

When cutting straight lines on aluminum flashing, selecting and using the proper snips correctly ensures accuracy and precision. Choose straight-cut aviation snips with sharp, well-maintained blades. Start by creating a small notch at the beginning of your cut line to guide the snips along the marked path. Hold the snips firmly at a perpendicular angle to the flashing to prevent bending the material. Make steady, controlled cuts along your marked line, taking your time to maintain accuracy. Periodically check that you’re following the cutting line correctly, making adjustments as needed. Mastering this technique will result in precise, clean edges on your aluminum flashing.

Making Curved Cuts With Tin Snips

For curved cuts on aluminum flashing, adjust your cutting technique to follow the desired curve with precision and control. Maintaining a steady hand and moving the snips smoothly along the curve is essential. Here are three vital tips for making precise curved cuts:

- Start with a Proper Grip: Hold tin snips firmly but not too tightly, ensuring you maintain control over the cutting direction.

- Use the Right Snips: Select specialized tin snips designed for curved cuts—typically left-cut or right-cut aviation snips depending on which direction you’re curving.

- Practice on Scrap Material: Before cutting your actual flashing, practice on scrap pieces to perfect your technique and achieve smoother curved cuts.

Safety Precautions and Tips

Always implement proper safety measures when cutting aluminum flashing to prevent injuries and ensure smooth cutting. Wear safety glasses to protect your eyes from metal fragments and gloves to prevent hand cuts. Secure the flashing firmly with clamps or in a vice to prevent slipping during cutting. Position yourself with a stable stance and clear cutting path. Ensure your cutting tools are sharp and appropriate for aluminum to maintain precision. Apply steady, consistent pressure while cutting and avoid forcing the tool through the metal. Take breaks when needed to prevent fatigue and maintain focus. Following these safety practices protects you and helps achieve accurate, clean cuts in your aluminum flashing.

Other Related Posts: